- Beyond Software: Why Your Business Needs More Than Just ShipStation or SkuVault Support

by Kim Wren

Running an eCommerce business is more than just having the right software. While tools like ShipStation and SkuVault are incredibly powerful, they don’t always provide the tailored support you need to optimize your workflows, help employees when they’re stuck, or ensure you’re using the right features for your unique business. That’s where we come in. Your Business First—Not Just Software Sales At ecommconnected, we offer support that prioritizes YOUR business, not just software upgrades or additional user licenses. Many software support teams focus on upselling—our focus is ensuring you’re getting the most out of your systems. What We Offer Our monthly service plans are designed to provide the ongoing support you need to keep your business running efficiently. With plans starting at just $250 per month, we provide: Why Ongoing Support Matters Software is just one piece of the puzzle. Your business needs expert guidance to ensure that every tool you use is working for you—not against you. Whether it’s refining picking and packing workflows, setting up automation rules, or troubleshooting technical issues, having dedicated support can make all the difference. Get the Help You Need Don’t settle for one-size-fits-all software support. Invest in a plan that actually considers your business needs first. Contact us today to learn how our monthly service plan can help you maximize ShipStation and SkuVault while improving your overall warehouse and fulfillment processes. Check out our services here

- From Chaos to Clarity: Organizing Your Small Business Storage Space

by Kim Wren

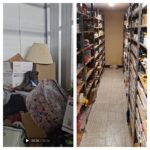

Running a small business often means you’re working out of a variety of spaces—whether it’s a basement, bedroom, garage, or a rented storage facility. It’s easy for these spaces to turn into a cluttered mess, making it difficult to find what you need when you need it. But with a little planning and the right tools, you can transform your storage from a chaotic pile of boxes to a well-organized inventory haven. Let’s explore how to take your space from looking like the first picture (a hot mess) to the second picture (an organized, efficient storage system). Step 1: Assess the Situation Before diving into organization, take a moment to assess your space. What items do you have? What kind of storage solutions do you need? This initial assessment will help you determine the amount of shelving, containers, and labels you’ll require. It will also give you a chance to declutter—donate, recycle, or sell items that you no longer need or that don’t serve your business anymore. Step 2: Create a Layout Plan Once you know what you’re working with, sketch out a layout plan (or call us to help you with that plan!). Consider the flow of how you access items. For example, place frequently used items at eye level or in easily accessible spots, and store seasonal or rarely used items higher up or further back. If you’re working in a smaller space like a bedroom or a basement, consider vertical storage options—shelves that go up to the ceiling can dramatically increase your storage capacity without taking up more floor space. Step 3: Invest in Shelving and Storage Solutions Good shelving is the backbone of an organized storage space. Depending on your space, this could mean heavy-duty metal shelves, plastic storage units, or wooden shelves. The key is to ensure that your shelves can hold the weight of your items and are adjustable to accommodate different box sizes. In the second picture, notice the neat rows of items sorted by type and size, making it easy to see what’s in stock at a glance. This level of organization helps in maintaining a well-functioning inventory system. Step 4: Implement an Inventory Tracking System An organized space isn’t just about where you put things; it’s also about knowing what you have and where it is at all times. This is where an inventory tracking system comes into play. Whether you use a dedicated software or a simple spreadsheet, keeping track of your inventory will save you time and money. Start by creating a catalog of your items. Each item should have a designated spot on the shelf and a corresponding entry in your tracking system. Include details such as item description, quantity, and location. Some businesses prefer using barcode systems, which allow for quick scanning and updating of inventory levels. Step 5: Label Everything Labels are your best friend when it comes to maintaining an organized space. Label the shelves, boxes, and containers so that anyone can find an item in an instant. Clear, consistent labeling will reduce confusion and ensure that everything goes back to its rightful place after use. Step 6: Regular Maintenance An organized space requires regular upkeep. Set aside time each week or month to tidy up, restock, and reorganize as needed. This routine maintenance will prevent your space from reverting to its former chaotic state. Conclusion: The Payoff Taking your storage space from a hot mess (like the one in the first picture) to an organized, well-oiled machine (as shown in the second picture) might seem daunting, but the payoff is worth it. Not only will you save time and reduce stress, but your business will also run more smoothly. You’ll be able to find what you need when you need it, keep better track of your inventory, and ultimately provide better service to your customers. Invest the time and effort into organizing your space today—it’s an investment that will pay dividends in the long run. For help, advice, or consulting on your space, warehouse management tools, and inventory management give me a call. I have been helping small businesses get more organized, and find the right software, for more than 10 years.

- Procedure & Processes for Different Stocking Styles

by Kim Wren

In today’s fast-paced business environment, effective inventory management is crucial to maintaining profitability and customer satisfaction. Whether you’re adopting Just in Time (JIT) stocking to minimize holding costs, employing Rolling Stocking to balance inventory levels, or leveraging Drop Shipping to streamline operations, the key to success lies in data-driven decision-making, agility, and strong supplier relationships. By integrating these business philosophies into your stocking procedures, you can optimize your inventory management, reduce costs, and enhance your ability to meet customer demands swiftly and efficiently. Explore our insights to discover how these strategies can transform your approach to inventory management. 1. Just in Time (JIT) Stocking Objective: Minimize inventory holding costs by receiving goods only when they are needed. Process: Philosophy: Focus on lean inventory management, reducing waste, and freeing up capital for other investments. 2. Rolling Stocking Objective: Maintain a balanced inventory of items with predictable demand and longer lead times. Process: Philosophy: Balance inventory levels to optimize cash flow, prevent stockouts, and reduce holding costs while ensuring product availability. 3. Drop Shipping Objective: Fulfill customer orders directly from the vendor, reducing the need for inventory storage and minimizing shipping costs. Process: Philosophy: Leverage vendor capabilities to reduce overhead, minimize risk, and offer a broader product range without the burden of inventory management. Business Philosophies for Stocking Procedures By implementing these procedures and philosophies, businesses can optimize their inventory management to support various stocking strategies, ensuring efficiency, profitability, and customer satisfaction.

- Warehouse Layout for Optimal Workflows: Tips for Success

by Kim Wren

We can take you from Point A to Point B! When it comes to running an efficient warehouse, the layout can make or break your operation. A well-thought-out design not only boosts productivity but also enhances safety, reduces errors, and ultimately, drives profitability. Whether you’re just setting up a new warehouse or optimizing an existing one, these key strategies will help you create a layout that supports optimal workflows. 1. Position Fast Movers Closest to Shippers In any warehouse, certain products are likely to fly off the shelves faster than others. These fast movers should be positioned as close to the shipping area as possible. By doing this, you reduce the travel time for pickers, speeding up the order fulfillment process and ensuring that these high-demand items get out the door quickly. Not only does this improve efficiency, but it also reduces the physical strain on your team. Less walking means less fatigue, which can lead to higher job satisfaction and lower turnover. Plus, when your fast movers are easily accessible, your pickers can complete more orders in less time, leading to higher throughput and better customer satisfaction. 2. Implement Alpha-Numeric Locations for Easy Identification Organizing your warehouse with alpha-numeric location markers is a game-changer. This system allows pickers and stockers to quickly and easily locate items, minimizing the time spent searching for products. Each aisle, shelf, and bin should be clearly labeled with a unique identifier, such as “A1-B2-C3,” where each component represents a specific section of the warehouse. Not only does this improve speed, but it also reduces errors. With a clear, easy-to-understand system, your team is less likely to pick the wrong item or place products in the wrong location. Over time, this leads to fewer mistakes and returns, saving your business money and enhancing your reputation with customers. 3. Create a Warehouse Map for Visual Aids Even with a solid alpha-numeric system in place, new employees or temporary workers can struggle to navigate a large warehouse. To address this, create a detailed map of your warehouse layout that can be used as a visual aid. Post copies of this map at strategic locations around the warehouse, such as near entry points, break areas, and at the end of major aisles. This map should clearly highlight the alpha-numeric zones, as well as key areas like receiving, shipping, and fast mover zones. You can even color-code different sections of the warehouse for added clarity. This visual aid will help workers orient themselves quickly, reducing confusion and speeding up their work. 4. Ensure Aisles Are Wide Enough for Equipment A common oversight in warehouse design is failing to provide adequate space for the equipment that will be used. Narrow aisles can create bottlenecks, slow down operations, and increase the risk of accidents. When planning your layout, make sure that your aisles are wide enough to accommodate forklifts, pallet jacks, and other machinery with ease. The width of your aisles will depend on the specific equipment you use, but as a general rule, they should be at least 10 to 12 feet wide for standard forklifts. Additionally, consider the turning radius of your equipment to ensure that there is enough space for safe and efficient maneuvering. Wider aisles not only improve safety but also allow for smoother and faster operations. How I Can Help: Professional Warehouse Layout and Optimization Services Designing a warehouse layout that meets these criteria requires a deep understanding of both your specific needs and the broader principles of efficient warehouse management. That’s where I come in. I specialize in helping businesses like yours optimize their warehouse and location layouts to maximize efficiency, reduce errors, and improve overall workflow. With years of experience in developing customized warehouse solutions, I can guide you through every step of the process—from initial planning and design to full implementation. Whether you need to revamp an existing space or are starting from scratch, I can create a layout that aligns with your operational goals and accommodates your equipment. I also offer expertise in implementing and optimizing Warehouse Management Systems (WMS), ensuring that your technology is fully integrated with your layout and processes. Why Choose My Services? Final Thoughts Optimizing your warehouse layout is crucial for creating an efficient, safe, and productive work environment. By strategically positioning fast movers, implementing an alpha-numeric system, creating a visual map, and ensuring adequate aisle width, you can significantly enhance your warehouse operations. These steps may require some upfront effort, but the long-term benefits—faster fulfillment, fewer errors, and happier employees—are well worth it. If you’re ready to take your warehouse to the next level, contact me today to discuss how I can help you design and implement a layout that supports optimal workflows and integrates seamlessly with your WMS. Let’s create a space that not only works for you but also drives your business forward.

- Unlock the Full Potential of Your WMS/IMS Software with Expert Guidance

by Kim Wren

our investment in a WMS or IMS should be making your life easier and your business more profitable. If that’s not the case, it’s time to explore why. With my expertise, I can transform your current system from a mere tool into a pivotal element of your business strategy.

by Kim WrenRunning a small business often means you’re working out of a variety of spaces—whether it’s a basement, bedroom, garage, or a rented storage facility. It’s easy for these spaces to turn into a cluttered mess, making it difficult to find what you need when you need it. But with a little planning and the right tools, you can transform your storage from a chaotic pile of boxes to a well-organized inventory haven. Let’s explore how to take your space from looking like the first picture (a hot mess) to the second picture (an organized, efficient storage system). Step 1: Assess the Situation Before diving into organization, take a moment to assess your space. What items do you have? What kind of storage solutions do you need? This initial assessment will help you determine the amount of shelving, containers, and labels you’ll require. It will also give you a chance to declutter—donate, recycle, or sell items that you no longer need or that don’t serve your business anymore. Step 2: Create a Layout Plan Once you know what you’re working with, sketch out a layout plan (or call us to help you with that plan!). Consider the flow of how you access items. For example, place frequently used items at eye level or in easily accessible spots, and store seasonal or rarely used items higher up or further back. If you’re working in a smaller space like a bedroom or a basement, consider vertical storage options—shelves that go up to the ceiling can dramatically increase your storage capacity without taking up more floor space. Step 3: Invest in Shelving and Storage Solutions Good shelving is the backbone of an organized storage space. Depending on your space, this could mean heavy-duty metal shelves, plastic storage units, or wooden shelves. The key is to ensure that your shelves can hold the weight of your items and are adjustable to accommodate different box sizes. In the second picture, notice the neat rows of items sorted by type and size, making it easy to see what’s in stock at a glance. This level of organization helps in maintaining a well-functioning inventory system. Step 4: Implement an Inventory Tracking System An organized space isn’t just about where you put things; it’s also about knowing what you have and where it is at all times. This is where an inventory tracking system comes into play. Whether you use a dedicated software or a simple spreadsheet, keeping track of your inventory will save you time and money. Start by creating a catalog of your items. Each item should have a designated spot on the shelf and a corresponding entry in your tracking system. Include details such as item description, quantity, and location. Some businesses prefer using barcode systems, which allow for quick scanning and updating of inventory levels. Step 5: Label Everything Labels are your best friend when it comes to maintaining an organized space. Label the shelves, boxes, and containers so that anyone can find an item in an instant. Clear, consistent labeling will reduce confusion and ensure that everything goes back to its rightful place after use. Step 6: Regular Maintenance An organized space requires regular upkeep. Set aside time each week or month to tidy up, restock, and reorganize as needed. This routine maintenance will prevent your space from reverting to its former chaotic state. Conclusion: The Payoff Taking your storage space from a hot mess (like the one in the first picture) to an organized, well-oiled machine (as shown in the second picture) might seem daunting, but the payoff is worth it. Not only will you save time and reduce stress, but your business will also run more smoothly. You’ll be able to find what you need when you need it, keep better track of your inventory, and ultimately provide better service to your customers. Invest the time and effort into organizing your space today—it’s an investment that will pay dividends in the long run. For help, advice, or consulting on your space, warehouse management tools, and inventory management give me a call. I have been helping small businesses get more organized, and find the right software, for more than 10 years.

by Kim WrenRunning a small business often means you’re working out of a variety of spaces—whether it’s a basement, bedroom, garage, or a rented storage facility. It’s easy for these spaces to turn into a cluttered mess, making it difficult to find what you need when you need it. But with a little planning and the right tools, you can transform your storage from a chaotic pile of boxes to a well-organized inventory haven. Let’s explore how to take your space from looking like the first picture (a hot mess) to the second picture (an organized, efficient storage system). Step 1: Assess the Situation Before diving into organization, take a moment to assess your space. What items do you have? What kind of storage solutions do you need? This initial assessment will help you determine the amount of shelving, containers, and labels you’ll require. It will also give you a chance to declutter—donate, recycle, or sell items that you no longer need or that don’t serve your business anymore. Step 2: Create a Layout Plan Once you know what you’re working with, sketch out a layout plan (or call us to help you with that plan!). Consider the flow of how you access items. For example, place frequently used items at eye level or in easily accessible spots, and store seasonal or rarely used items higher up or further back. If you’re working in a smaller space like a bedroom or a basement, consider vertical storage options—shelves that go up to the ceiling can dramatically increase your storage capacity without taking up more floor space. Step 3: Invest in Shelving and Storage Solutions Good shelving is the backbone of an organized storage space. Depending on your space, this could mean heavy-duty metal shelves, plastic storage units, or wooden shelves. The key is to ensure that your shelves can hold the weight of your items and are adjustable to accommodate different box sizes. In the second picture, notice the neat rows of items sorted by type and size, making it easy to see what’s in stock at a glance. This level of organization helps in maintaining a well-functioning inventory system. Step 4: Implement an Inventory Tracking System An organized space isn’t just about where you put things; it’s also about knowing what you have and where it is at all times. This is where an inventory tracking system comes into play. Whether you use a dedicated software or a simple spreadsheet, keeping track of your inventory will save you time and money. Start by creating a catalog of your items. Each item should have a designated spot on the shelf and a corresponding entry in your tracking system. Include details such as item description, quantity, and location. Some businesses prefer using barcode systems, which allow for quick scanning and updating of inventory levels. Step 5: Label Everything Labels are your best friend when it comes to maintaining an organized space. Label the shelves, boxes, and containers so that anyone can find an item in an instant. Clear, consistent labeling will reduce confusion and ensure that everything goes back to its rightful place after use. Step 6: Regular Maintenance An organized space requires regular upkeep. Set aside time each week or month to tidy up, restock, and reorganize as needed. This routine maintenance will prevent your space from reverting to its former chaotic state. Conclusion: The Payoff Taking your storage space from a hot mess (like the one in the first picture) to an organized, well-oiled machine (as shown in the second picture) might seem daunting, but the payoff is worth it. Not only will you save time and reduce stress, but your business will also run more smoothly. You’ll be able to find what you need when you need it, keep better track of your inventory, and ultimately provide better service to your customers. Invest the time and effort into organizing your space today—it’s an investment that will pay dividends in the long run. For help, advice, or consulting on your space, warehouse management tools, and inventory management give me a call. I have been helping small businesses get more organized, and find the right software, for more than 10 years. by Kim WrenIn today’s fast-paced business environment, effective inventory management is crucial to maintaining profitability and customer satisfaction. Whether you’re adopting Just in Time (JIT) stocking to minimize holding costs, employing Rolling Stocking to balance inventory levels, or leveraging Drop Shipping to streamline operations, the key to success lies in data-driven decision-making, agility, and strong supplier relationships. By integrating these business philosophies into your stocking procedures, you can optimize your inventory management, reduce costs, and enhance your ability to meet customer demands swiftly and efficiently. Explore our insights to discover how these strategies can transform your approach to inventory management. 1. Just in Time (JIT) Stocking Objective: Minimize inventory holding costs by receiving goods only when they are needed. Process: Philosophy: Focus on lean inventory management, reducing waste, and freeing up capital for other investments. 2. Rolling Stocking Objective: Maintain a balanced inventory of items with predictable demand and longer lead times. Process: Philosophy: Balance inventory levels to optimize cash flow, prevent stockouts, and reduce holding costs while ensuring product availability. 3. Drop Shipping Objective: Fulfill customer orders directly from the vendor, reducing the need for inventory storage and minimizing shipping costs. Process: Philosophy: Leverage vendor capabilities to reduce overhead, minimize risk, and offer a broader product range without the burden of inventory management. Business Philosophies for Stocking Procedures By implementing these procedures and philosophies, businesses can optimize their inventory management to support various stocking strategies, ensuring efficiency, profitability, and customer satisfaction.

by Kim WrenIn today’s fast-paced business environment, effective inventory management is crucial to maintaining profitability and customer satisfaction. Whether you’re adopting Just in Time (JIT) stocking to minimize holding costs, employing Rolling Stocking to balance inventory levels, or leveraging Drop Shipping to streamline operations, the key to success lies in data-driven decision-making, agility, and strong supplier relationships. By integrating these business philosophies into your stocking procedures, you can optimize your inventory management, reduce costs, and enhance your ability to meet customer demands swiftly and efficiently. Explore our insights to discover how these strategies can transform your approach to inventory management. 1. Just in Time (JIT) Stocking Objective: Minimize inventory holding costs by receiving goods only when they are needed. Process: Philosophy: Focus on lean inventory management, reducing waste, and freeing up capital for other investments. 2. Rolling Stocking Objective: Maintain a balanced inventory of items with predictable demand and longer lead times. Process: Philosophy: Balance inventory levels to optimize cash flow, prevent stockouts, and reduce holding costs while ensuring product availability. 3. Drop Shipping Objective: Fulfill customer orders directly from the vendor, reducing the need for inventory storage and minimizing shipping costs. Process: Philosophy: Leverage vendor capabilities to reduce overhead, minimize risk, and offer a broader product range without the burden of inventory management. Business Philosophies for Stocking Procedures By implementing these procedures and philosophies, businesses can optimize their inventory management to support various stocking strategies, ensuring efficiency, profitability, and customer satisfaction. by Kim WrenWe can take you from Point A to Point B! When it comes to running an efficient warehouse, the layout can make or break your operation. A well-thought-out design not only boosts productivity but also enhances safety, reduces errors, and ultimately, drives profitability. Whether you’re just setting up a new warehouse or optimizing an existing one, these key strategies will help you create a layout that supports optimal workflows. 1. Position Fast Movers Closest to Shippers In any warehouse, certain products are likely to fly off the shelves faster than others. These fast movers should be positioned as close to the shipping area as possible. By doing this, you reduce the travel time for pickers, speeding up the order fulfillment process and ensuring that these high-demand items get out the door quickly. Not only does this improve efficiency, but it also reduces the physical strain on your team. Less walking means less fatigue, which can lead to higher job satisfaction and lower turnover. Plus, when your fast movers are easily accessible, your pickers can complete more orders in less time, leading to higher throughput and better customer satisfaction. 2. Implement Alpha-Numeric Locations for Easy Identification Organizing your warehouse with alpha-numeric location markers is a game-changer. This system allows pickers and stockers to quickly and easily locate items, minimizing the time spent searching for products. Each aisle, shelf, and bin should be clearly labeled with a unique identifier, such as “A1-B2-C3,” where each component represents a specific section of the warehouse. Not only does this improve speed, but it also reduces errors. With a clear, easy-to-understand system, your team is less likely to pick the wrong item or place products in the wrong location. Over time, this leads to fewer mistakes and returns, saving your business money and enhancing your reputation with customers. 3. Create a Warehouse Map for Visual Aids Even with a solid alpha-numeric system in place, new employees or temporary workers can struggle to navigate a large warehouse. To address this, create a detailed map of your warehouse layout that can be used as a visual aid. Post copies of this map at strategic locations around the warehouse, such as near entry points, break areas, and at the end of major aisles. This map should clearly highlight the alpha-numeric zones, as well as key areas like receiving, shipping, and fast mover zones. You can even color-code different sections of the warehouse for added clarity. This visual aid will help workers orient themselves quickly, reducing confusion and speeding up their work. 4. Ensure Aisles Are Wide Enough for Equipment A common oversight in warehouse design is failing to provide adequate space for the equipment that will be used. Narrow aisles can create bottlenecks, slow down operations, and increase the risk of accidents. When planning your layout, make sure that your aisles are wide enough to accommodate forklifts, pallet jacks, and other machinery with ease. The width of your aisles will depend on the specific equipment you use, but as a general rule, they should be at least 10 to 12 feet wide for standard forklifts. Additionally, consider the turning radius of your equipment to ensure that there is enough space for safe and efficient maneuvering. Wider aisles not only improve safety but also allow for smoother and faster operations. How I Can Help: Professional Warehouse Layout and Optimization Services Designing a warehouse layout that meets these criteria requires a deep understanding of both your specific needs and the broader principles of efficient warehouse management. That’s where I come in. I specialize in helping businesses like yours optimize their warehouse and location layouts to maximize efficiency, reduce errors, and improve overall workflow. With years of experience in developing customized warehouse solutions, I can guide you through every step of the process—from initial planning and design to full implementation. Whether you need to revamp an existing space or are starting from scratch, I can create a layout that aligns with your operational goals and accommodates your equipment. I also offer expertise in implementing and optimizing Warehouse Management Systems (WMS), ensuring that your technology is fully integrated with your layout and processes. Why Choose My Services? Final Thoughts Optimizing your warehouse layout is crucial for creating an efficient, safe, and productive work environment. By strategically positioning fast movers, implementing an alpha-numeric system, creating a visual map, and ensuring adequate aisle width, you can significantly enhance your warehouse operations. These steps may require some upfront effort, but the long-term benefits—faster fulfillment, fewer errors, and happier employees—are well worth it. If you’re ready to take your warehouse to the next level, contact me today to discuss how I can help you design and implement a layout that supports optimal workflows and integrates seamlessly with your WMS. Let’s create a space that not only works for you but also drives your business forward.

by Kim WrenWe can take you from Point A to Point B! When it comes to running an efficient warehouse, the layout can make or break your operation. A well-thought-out design not only boosts productivity but also enhances safety, reduces errors, and ultimately, drives profitability. Whether you’re just setting up a new warehouse or optimizing an existing one, these key strategies will help you create a layout that supports optimal workflows. 1. Position Fast Movers Closest to Shippers In any warehouse, certain products are likely to fly off the shelves faster than others. These fast movers should be positioned as close to the shipping area as possible. By doing this, you reduce the travel time for pickers, speeding up the order fulfillment process and ensuring that these high-demand items get out the door quickly. Not only does this improve efficiency, but it also reduces the physical strain on your team. Less walking means less fatigue, which can lead to higher job satisfaction and lower turnover. Plus, when your fast movers are easily accessible, your pickers can complete more orders in less time, leading to higher throughput and better customer satisfaction. 2. Implement Alpha-Numeric Locations for Easy Identification Organizing your warehouse with alpha-numeric location markers is a game-changer. This system allows pickers and stockers to quickly and easily locate items, minimizing the time spent searching for products. Each aisle, shelf, and bin should be clearly labeled with a unique identifier, such as “A1-B2-C3,” where each component represents a specific section of the warehouse. Not only does this improve speed, but it also reduces errors. With a clear, easy-to-understand system, your team is less likely to pick the wrong item or place products in the wrong location. Over time, this leads to fewer mistakes and returns, saving your business money and enhancing your reputation with customers. 3. Create a Warehouse Map for Visual Aids Even with a solid alpha-numeric system in place, new employees or temporary workers can struggle to navigate a large warehouse. To address this, create a detailed map of your warehouse layout that can be used as a visual aid. Post copies of this map at strategic locations around the warehouse, such as near entry points, break areas, and at the end of major aisles. This map should clearly highlight the alpha-numeric zones, as well as key areas like receiving, shipping, and fast mover zones. You can even color-code different sections of the warehouse for added clarity. This visual aid will help workers orient themselves quickly, reducing confusion and speeding up their work. 4. Ensure Aisles Are Wide Enough for Equipment A common oversight in warehouse design is failing to provide adequate space for the equipment that will be used. Narrow aisles can create bottlenecks, slow down operations, and increase the risk of accidents. When planning your layout, make sure that your aisles are wide enough to accommodate forklifts, pallet jacks, and other machinery with ease. The width of your aisles will depend on the specific equipment you use, but as a general rule, they should be at least 10 to 12 feet wide for standard forklifts. Additionally, consider the turning radius of your equipment to ensure that there is enough space for safe and efficient maneuvering. Wider aisles not only improve safety but also allow for smoother and faster operations. How I Can Help: Professional Warehouse Layout and Optimization Services Designing a warehouse layout that meets these criteria requires a deep understanding of both your specific needs and the broader principles of efficient warehouse management. That’s where I come in. I specialize in helping businesses like yours optimize their warehouse and location layouts to maximize efficiency, reduce errors, and improve overall workflow. With years of experience in developing customized warehouse solutions, I can guide you through every step of the process—from initial planning and design to full implementation. Whether you need to revamp an existing space or are starting from scratch, I can create a layout that aligns with your operational goals and accommodates your equipment. I also offer expertise in implementing and optimizing Warehouse Management Systems (WMS), ensuring that your technology is fully integrated with your layout and processes. Why Choose My Services? Final Thoughts Optimizing your warehouse layout is crucial for creating an efficient, safe, and productive work environment. By strategically positioning fast movers, implementing an alpha-numeric system, creating a visual map, and ensuring adequate aisle width, you can significantly enhance your warehouse operations. These steps may require some upfront effort, but the long-term benefits—faster fulfillment, fewer errors, and happier employees—are well worth it. If you’re ready to take your warehouse to the next level, contact me today to discuss how I can help you design and implement a layout that supports optimal workflows and integrates seamlessly with your WMS. Let’s create a space that not only works for you but also drives your business forward. by Kim Wrenour investment in a WMS or IMS should be making your life easier and your business more profitable. If that’s not the case, it’s time to explore why. With my expertise, I can transform your current system from a mere tool into a pivotal element of your business strategy.

by Kim Wrenour investment in a WMS or IMS should be making your life easier and your business more profitable. If that’s not the case, it’s time to explore why. With my expertise, I can transform your current system from a mere tool into a pivotal element of your business strategy.