We can take you from Point A to Point B!

When it comes to running an efficient warehouse, the layout can make or break your operation. A well-thought-out design not only boosts productivity but also enhances safety, reduces errors, and ultimately, drives profitability. Whether you’re just setting up a new warehouse or optimizing an existing one, these key strategies will help you create a layout that supports optimal workflows.

1. Position Fast Movers Closest to Shippers

In any warehouse, certain products are likely to fly off the shelves faster than others. These fast movers should be positioned as close to the shipping area as possible. By doing this, you reduce the travel time for pickers, speeding up the order fulfillment process and ensuring that these high-demand items get out the door quickly.

Not only does this improve efficiency, but it also reduces the physical strain on your team. Less walking means less fatigue, which can lead to higher job satisfaction and lower turnover. Plus, when your fast movers are easily accessible, your pickers can complete more orders in less time, leading to higher throughput and better customer satisfaction.

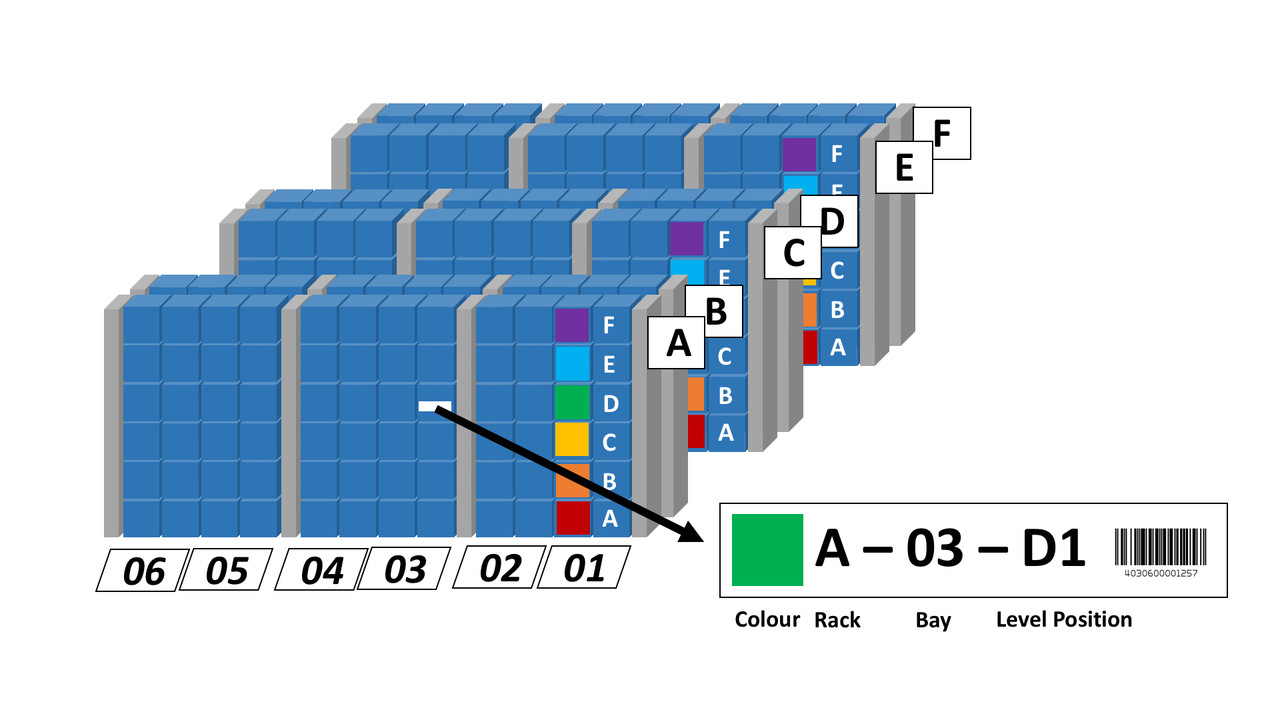

2. Implement Alpha-Numeric Locations for Easy Identification

Organizing your warehouse with alpha-numeric location markers is a game-changer. This system allows pickers and stockers to quickly and easily locate items, minimizing the time spent searching for products. Each aisle, shelf, and bin should be clearly labeled with a unique identifier, such as “A1-B2-C3,” where each component represents a specific section of the warehouse.

Not only does this improve speed, but it also reduces errors. With a clear, easy-to-understand system, your team is less likely to pick the wrong item or place products in the wrong location. Over time, this leads to fewer mistakes and returns, saving your business money and enhancing your reputation with customers.

3. Create a Warehouse Map for Visual Aids

Even with a solid alpha-numeric system in place, new employees or temporary workers can struggle to navigate a large warehouse. To address this, create a detailed map of your warehouse layout that can be used as a visual aid. Post copies of this map at strategic locations around the warehouse, such as near entry points, break areas, and at the end of major aisles.

This map should clearly highlight the alpha-numeric zones, as well as key areas like receiving, shipping, and fast mover zones. You can even color-code different sections of the warehouse for added clarity. This visual aid will help workers orient themselves quickly, reducing confusion and speeding up their work.

4. Ensure Aisles Are Wide Enough for Equipment

A common oversight in warehouse design is failing to provide adequate space for the equipment that will be used. Narrow aisles can create bottlenecks, slow down operations, and increase the risk of accidents. When planning your layout, make sure that your aisles are wide enough to accommodate forklifts, pallet jacks, and other machinery with ease.

The width of your aisles will depend on the specific equipment you use, but as a general rule, they should be at least 10 to 12 feet wide for standard forklifts. Additionally, consider the turning radius of your equipment to ensure that there is enough space for safe and efficient maneuvering. Wider aisles not only improve safety but also allow for smoother and faster operations.

How I Can Help: Professional Warehouse Layout and Optimization Services

Designing a warehouse layout that meets these criteria requires a deep understanding of both your specific needs and the broader principles of efficient warehouse management. That’s where I come in.

I specialize in helping businesses like yours optimize their warehouse and location layouts to maximize efficiency, reduce errors, and improve overall workflow. With years of experience in developing customized warehouse solutions, I can guide you through every step of the process—from initial planning and design to full implementation.

Whether you need to revamp an existing space or are starting from scratch, I can create a layout that aligns with your operational goals and accommodates your equipment. I also offer expertise in implementing and optimizing Warehouse Management Systems (WMS), ensuring that your technology is fully integrated with your layout and processes.

Why Choose My Services?

- Customized Solutions: Every business is unique, and so are its warehouse needs. I tailor my services to fit your specific operational requirements, whether you’re in e-commerce, retail, or any other industry.

- Expertise in WMS Implementation: A well-designed warehouse layout goes hand-in-hand with an optimized Warehouse Management System. I help businesses choose the right equipment, shelving, storage, and WMS to fit their business needs. I also ensure you get the set-up and training needed to work seamlessly with your warehouse operations.

- Comprehensive Support: From initial consultation to ongoing optimization, I provide end-to-end support to ensure your warehouse operates at peak efficiency.

- Proven Track Record: I have successfully worked with businesses generating $10-$25 million in annual sales, helping them streamline their operations and increase profitability through strategic warehouse design.

Final Thoughts

Optimizing your warehouse layout is crucial for creating an efficient, safe, and productive work environment. By strategically positioning fast movers, implementing an alpha-numeric system, creating a visual map, and ensuring adequate aisle width, you can significantly enhance your warehouse operations. These steps may require some upfront effort, but the long-term benefits—faster fulfillment, fewer errors, and happier employees—are well worth it.

If you’re ready to take your warehouse to the next level, contact me today to discuss how I can help you design and implement a layout that supports optimal workflows and integrates seamlessly with your WMS. Let’s create a space that not only works for you but also drives your business forward.