In today’s fast-paced business environment, effective inventory management is crucial to maintaining profitability and customer satisfaction. Whether you’re adopting Just in Time (JIT) stocking to minimize holding costs, employing Rolling Stocking to balance inventory levels, or leveraging Drop Shipping to streamline operations, the key to success lies in data-driven decision-making, agility, and strong supplier relationships. By integrating these business philosophies into your stocking procedures, you can optimize your inventory management, reduce costs, and enhance your ability to meet customer demands swiftly and efficiently.

Explore our insights to discover how these strategies can transform your approach to inventory management.

1. Just in Time (JIT) Stocking

Objective: Minimize inventory holding costs by receiving goods only when they are needed.

Process:

- Vendor Relationships: Establish strong relationships with vendors who can deliver quickly (typically within 1-2 days). Regularly communicate sales data to vendors to ensure they stock sufficient inventory to meet your needs.

- Sales Monitoring: Utilize sales data analytics to track product demand in real-time. Set up alerts for products that are reaching reorder points.

- Recurring Orders: For high-turnover items, consider setting up automatic reorders based on historical sales patterns to ensure continuous availability without overstocking.

- Order Confirmation: Before confirming a sale to the customer, verify the availability with the vendor to avoid stockouts.

- Cash Flow Management: Regularly review cash flow to ensure that the JIT model does not create financial strain due to timing mismatches between revenue and payments to vendors.

Philosophy: Focus on lean inventory management, reducing waste, and freeing up capital for other investments.

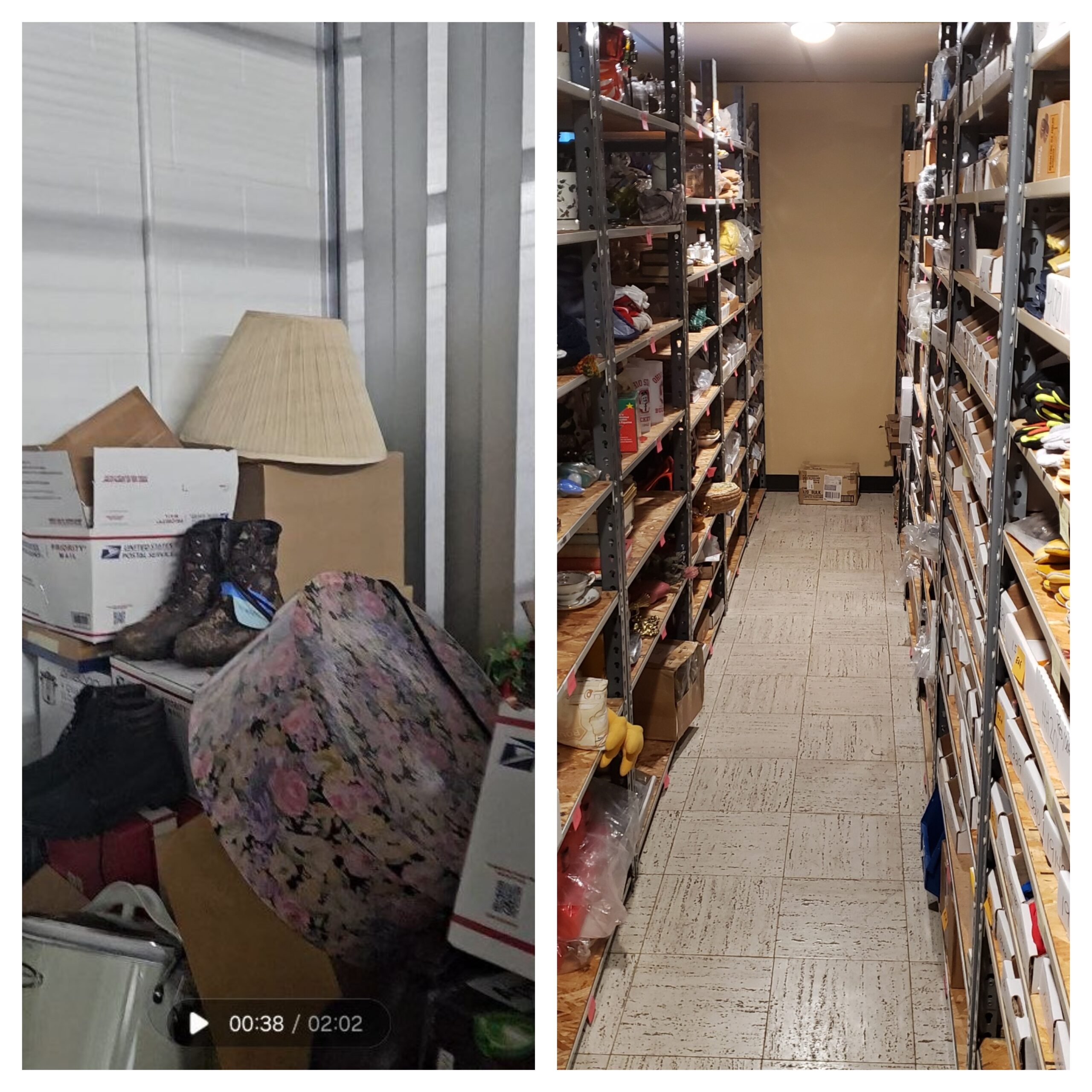

2. Rolling Stocking

Objective: Maintain a balanced inventory of items with predictable demand and longer lead times.

Process:

- Inventory Forecasting: Use historical sales data to predict future demand and establish minimum and maximum stock levels for each item.

- Stock Replenishment: Replenish stock regularly based on the established min/max levels. Adjust these levels periodically based on changing sales patterns.

- Lead Time Management: Factor in supplier lead times when determining reorder points. Ensure that orders are placed well in advance of stock depletion.

- Safety Stock: Maintain safety stock for high-demand items to cover unexpected spikes in demand or delays in replenishment.

- Regular Audits: Conduct regular inventory audits to ensure accuracy in stock levels and to identify slow-moving items that might need promotional efforts or discounts.

Philosophy: Balance inventory levels to optimize cash flow, prevent stockouts, and reduce holding costs while ensuring product availability.

3. Drop Shipping

Objective: Fulfill customer orders directly from the vendor, reducing the need for inventory storage and minimizing shipping costs.

Process:

- Vendor Selection: Partner with reliable vendors who offer efficient drop-shipping services. Ensure that they can meet your quality standards and delivery expectations.

- Order Integration: Integrate your sales platform with the vendor’s inventory and order systems to automate order processing and updates.

- Quality Control: Set up quality control checks to ensure that vendors are maintaining product standards and delivering as promised.

- Shipping Optimization: Choose vendors that are geographically closer to the customer to reduce shipping times and costs.

- Customer Communication: Clearly communicate shipping expectations to customers, including who will be handling their order and potential delivery times.

Philosophy: Leverage vendor capabilities to reduce overhead, minimize risk, and offer a broader product range without the burden of inventory management.

Business Philosophies for Stocking Procedures

- Data-Driven Decision Making: Utilize real-time sales data and predictive analytics to make informed decisions on inventory levels, reorder points, and stocking strategies.

- Flexibility and Agility: Maintain flexibility in your stocking strategies to adapt quickly to market changes, supplier issues, or shifts in customer demand.

- Supplier Collaboration: Build strong partnerships with suppliers to ensure reliability, negotiate favorable terms, and collaborate on inventory management.

- Customer-Centric Approach: Focus on customer satisfaction by ensuring product availability, minimizing shipping times, and providing transparent communication regarding order fulfillment.

- Cost Efficiency: Continuously seek ways to reduce costs associated with inventory management, including optimizing stocking levels, reducing holding costs, and minimizing shipping expenses.

By implementing these procedures and philosophies, businesses can optimize their inventory management to support various stocking strategies, ensuring efficiency, profitability, and customer satisfaction.